War in Ukraine: when political risks upturn commodity markets

The Russian invasion has pushed up prices and highlighted the threat of raw materials becoming a foreign policy weapon

Emiko Terazono and Neil Hume in London and Nic Fildes in Sydney

Like many people, Gary Sharkey has been constantly checking the news for the latest developments on the Russian invasion of Ukraine.

But his interest is not just personal: as procurement director of Hovis, one of Britain’s biggest bakers, Sharkey is responsible for buying in everything from grains for bread to steel for machinery.

Russia and Ukraine are both important grain exporters, between them accounting for almost a third of the world’s traded wheat.

For Hovis, the surge in wheat prices caused by the invasion and the subsequent sanctions on Russia have important cost implications for its business.

“Ukraine and Russia — the flow of grains from the Black Sea is so important for the world market,” says Sharkey as exports from both countries have virtually come to a halt.

It is not just the grains.

Sharkey also points to the jump in the price of aluminium.

The price of the lightweight metal, used in everything from cars to beer cans and bread tins, is on course to hit a record high above $3,475 a tonne — partly a reflection of the fact that Russia is the second-largest exporter.

“Everything has gone up.

There is a political risk premium built into a lot of the products,” says the 55-year-old executive, noting the 51 per cent rise in wheat and the near 600 per cent per cent rise in wholesale European gas prices over the past 12 months.

Traders, brokers and clerks on the floor of the open outcry pit at the London Metal Exchange. Commodity traders and purchasing managers are worried about the way many raw materials have the potential to be used as weapons of foreign policy © Chris J Ratcliffe/Bloomberg

Traders, brokers and clerks on the floor of the open outcry pit at the London Metal Exchange. Commodity traders and purchasing managers are worried about the way many raw materials have the potential to be used as weapons of foreign policy © Chris J Ratcliffe/BloombergThe invasion of Ukraine has cast a pall over the commodities sector because it has also made it impossible to ignore the geopolitical faultlines that run through so many of the markets for key raw materials.

The political risks keep mounting.

The conflict itself and sanctions on Russia are causing disruption in a number of markets — especially wheat.

The rising cost of energy has important ripple effects in other commodity markets, including for the cost of fertiliser used by farmers.

On top of that, commodity traders and purchasing managers are growing increasingly worried about the way that many raw materials have the potential to be used as weapons of foreign policy — especially if a new cold war develops that divides Russia, and potentially China, from the west.

For most of the past three decades, the commodities industry has been one of the most striking examples of globalisation, which has created vast riches for the trading houses that connect buyers and sellers of raw materials.

Neon

40-50%

Per cent of all exports of neon come from Russia and Ukraine.

Neon is a byproduct of steel manufacturing which is a critical raw material for chip manufacturing.

When Russia entered eastern Ukraine in 2014, the price of neon jumped 600 per cent, causing disruption in the semiconductor industry

Although many individual projects in areas such as mining were always wrapped up in politics, the markets themselves have been built around the expectation of open global supply.

Procurement executives such as Sharkey at Hovis worried about prices but much less about being able to actually source the raw materials they need.

The shift in mindset in the commodities sector has been building for a decade.

As tensions between the US and China have grown, Beijing’s control of supplies of rare earths — metals used in many aspects of manufacturing — raised concerns that raw material supplies could become political weapons.

But over the past two years, two separate events have concentrated minds even further.

The Covid-19 pandemic highlighted the perils of relying on a handful of countries or companies, which had led to severe supply chain disruptions.

Now from grains to energy to metals, Russia’s invasion of Ukraine has served as a reminder of how some countries wield considerable influence over raw material supplies thanks to their large market share of vital commodities.

As well as being Europe’s main supplier of gas, Russia is also dominant in the markets for a number of other important commodities, such as oil, wheat, aluminium, and palladium.

“Commodities have been weaponised for a long, long time . . . its always a question of when does a state pull the trigger,” says Frank Fannon, former assistant US secretary of state for energy resources.

The short-term response to the Ukraine war from some companies and governments has been to increase stockpiles of important raw materials.

In the long-run, it is forcing the industry to consider alternative supply chains that can bypass the likely economic and financial conflict that is building between Russia and the west.

“Definitely the world is much more concerned about the problem [of geopolitics] than it was 10-15 years ago,” says Jean-Francois Lambert, a former banker and commodities consultant who advises financial institutions and trading firms.

“Then it was about globalisation.

It was just about efficient supply chains.

Now people are worrying, are we going to have supply, are we going to have access?”

Weaponising gas

Market shocks from producers controlling a large share of production of certain commodities are not new.

The oil shock in the 1970s, when Opec’s oil embargo led to soaring crude oil prices, caused stagflation among oil-importing countries around the globe.

Since then, trade has become more globalised and markets interconnected.

But as businesses and governments sought to cut costs in their supply chains, they inadvertently became more reliant on certain producers, from grains to computer chips, leaving them vulnerable to sudden disruption in product flows.

The prospect of natural resources being used as a weapon has been brought to life by Russia’s use of gas exports to Europe.

Russia accounts for about 40 per cent of the EU’s gas consumption.

But, in the fourth quarter of last year, Russian exports to north-west Europe fell between 20 and 25 per cent, according to the International Energy Agency, after Russia’s state-backed gas company Gazprom adopted a strategy of only meeting long-term contractual commitments and not offering extra supplies in the spot market.

Natural gas

17%

Per cent of global natural gas is produced in Russia.

The invasion of Ukraine has served as a reminder of how some countries wield considerable influence over raw material supplies such as natural gas

In January, Fatih Birol, head of the IEA, blamed rising gas prices on Russia withholding gas from Europe.

“We believe there are strong elements of tightness in the European gas market due to Russia’s behaviour,” he said.

Even as Germany last week halted the approval process for Nord Stream 2, a tweet from Dmitry Medvedev, former president and deputy head of Russia’s security council, was considered by some to be veiled threat about the region’s reliance on Russian gas.

“Welcome to the brave new world where Europeans will soon be paying €2,000 per 1,000 cubic meters of gas!” Medvedev said.

“Any time there is a concentration of supplies, then there is a risk that is hard to avoid,” says Randolph Bell, director of global energy at US international relations think-tank the Atlantic Council.

“Clearly [Russia is] using gas as a political tool.”

For analysts, the imposition of unprecedented sanctions on Russia’s central bank — which has caused a slump in the rouble and has been accompanied by declarations of “economic war” by European politicians — only increases the risk that Russia could withhold supplies of certain commodities.

If that happens, Russia’s dominance in certain metals and rare gases could have repercussions in multiple supply chains.

When aluminium company Rusal was blacklisted by financial institutions in 2018 after US sanctions, prices soared by a third, wreaking havoc in the car industry.

Palladium

40%

Per cent of the world’s palladium is produced in Russia.

The chemical element is used by carmakers to remove toxic emissions from exhaust fumes

The country is also a key producer of palladium, which carmakers use to remove toxic emissions from exhaust fumes, as well as platinum, copper and nickel, which are used in the batteries that power electric vehicles.

Russia and Ukraine are also the dominant suppliers of neon, an odourless gas that is a byproduct of steel manufacturing and is a critical raw material for chip manufacturing.

Neon is sourced and purified by several specialised Ukrainian companies, according to US research firm Techcet.

When Russia invaded eastern Ukraine in 2014, the price of neon jumped 600 per cent, almost overnight, causing massive disruption in the semiconductor industry.

“We anticipate an extended period of geopolitical tensions and elevated risk premiums across all underlying commodities following Russia’s invasion of Ukraine.

Russia has a far-reaching impact across global commodity markets, and the unfolding conflict has vast implications, not least higher prices,” said Natasha Kaneva, analyst at JPMorgan.

Perhaps one of the more worrying effects of the war in Ukraine has been the impact on grains and food prices.

The conflict comes at a time when food prices are already high, the result of poor harvests around the world.

Ukraine still has sizeable inventories to export from last year’s harvest, and the export disruption could “have dire consequences for food insecurity in already-fragile countries dependent on Ukrainian grain,” says Caitlin Welsh, director of the global food security programme at the Center for Strategic and International Studies, a US think-tank.

For the 14 countries where Ukrainian wheat is an essential import, almost half already suffer from severe food insecurity, including Lebanon and Yemen, according to CSIS.

But the impact would not be limited to these countries.

Russia’s invasion has caused energy prices to soar, and risks “pushing food insecurity skyward”, she says.

Labourers fill bags with gypsum fertiliser in Dhaka, Bangladesh. An acute shortage of fertilisers gripped rural India — which relies on overseas purchases for about 40% of its key crop nutrients — in the final months of 2021 © Ahmed Salahuddin/NurPhoto/Getty

Labourers fill bags with gypsum fertiliser in Dhaka, Bangladesh. An acute shortage of fertilisers gripped rural India — which relies on overseas purchases for about 40% of its key crop nutrients — in the final months of 2021 © Ahmed Salahuddin/NurPhoto/GettyEven before Moscow’s attack on Ukraine, growing geopolitical tensions from Europe had seeped into global food markets.

Prices for key fertilisers jumped last year after the EU announced sanctions over human rights abuses against Belarus, a leading potash producer, and China and Russia, also large fertiliser exporters, put in place export curbs to safeguard domestic supply.

An acute shortage of fertilisers gripped rural India — which relies on overseas purchases for about 40 per cent of its key crop nutrients — in the final months of 2021, leading to protests and clashes with the police in the central and northern parts of the country.

Ganesh Nanote, a farmer whose crops range from cotton to grains in India’s state of Maharashtra, was caught up in the scramble for key plant nutrients ahead of the planting season for the winter crop.

“There was a shortage of DAP [diammonium phosphate] as well as potash,” he says, adding that although he managed to get alternative nutrients for a higher price, his chickpea, banana and onion crops were affected.

“The rise in fertiliser prices has led to losses.”

Analysts expect prices for phosphate to remain high until China lifts its export ban in the middle of the year, while tensions surrounding Belarus are unlikely to recede any time soon.

“It’s difficult to see that [potash] premium going down,” says Chris Lawson, head of fertilisers at consultancy CRU.

Some analysts believe that growing Russian influence in former Soviet states could eventually create a situation where Moscow has strong influence over the global grains market — especially if it were to prevail in Ukraine.

Belarus is now closely allied to Russia, while Moscow recently sent troops to shore up the government in Kazakhstan, another large wheat producer.

“We can start to see food becoming a weapon again in some strategic game,” says David Laborde, senior research fellow at International Food Policy Research Institute, the agricultural policy think-tank.

A man carries fresh loaves of bread at a bakery in the El Menzah area of Tunis, Egypt. The country has stocked up on wheat, with the government saying it has enough of the staple to last until November © Fethi Belaid/AFP/Getty

A man carries fresh loaves of bread at a bakery in the El Menzah area of Tunis, Egypt. The country has stocked up on wheat, with the government saying it has enough of the staple to last until November © Fethi Belaid/AFP/GettyAware of the heightening anxiety over the concentration in commodity supply, some governments and companies are taking steps to try and mitigate the effects by increasing inventories.

“People are now building more buffer inventories compared with 10 or 15 years ago.

We saw that coming already from the Covid-era.

Everyone is realising that efficient supply chains are for when the world was perfect, for normal times,” says Lambert.

Egypt, for example, has stocked up on its wheat, with the government saying it had enough of the staple until November from imports and the expected local harvest.

The minister of supply recently said the tensions between Russia and Ukraine made for “a state of uncertainty in the market”, and that Egypt had already diversified its wheat purchases and was in discussions to hedge its buying with investment banks.

Alternative supply chains

If stockpiling is a short-term reaction to the crisis, the long-term response might repeat what has happened over the past decade in rare earths, the minerals used in high-tech products from wind turbines to electric vehicles.

China controls about four-fifths of global output, and its readiness to use its dominant position came to the fore in 2010, when it cut limited exports, leading to a surge in prices.

“The problem with China is the concentration of supply chain power they have.

They have shown [a willingness] to use that concentration of power to realise geopolitical muscle,” says Bell at the Atlantic Council.

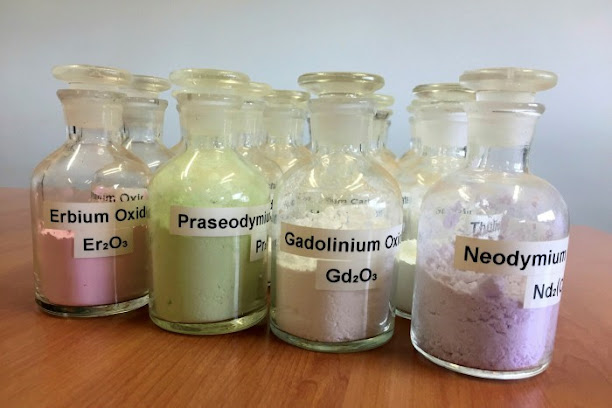

A selection of rare earth minerals produced by Australia’s Lynas Corp from its Mount Weld operations. Countries such as Australia and South Africa are primed to fill the demand for ‘non-China’ minerals © Melanie Burton/Reuters

A selection of rare earth minerals produced by Australia’s Lynas Corp from its Mount Weld operations. Countries such as Australia and South Africa are primed to fill the demand for ‘non-China’ minerals © Melanie Burton/ReutersIn order to reduce dependence on China for rare earths, the US, Japan and Australia have spent the past decade planning ways to develop new supplies.

Last week President Joe Biden announced that the government was investing $35mn in MP Materials, currently America’s only rare earth mining and processing operation, in California.

The US defence department has backed several projects, including the huge Lynas project in Kalgoorlie, in Western Australia.

The state is the home to several other new mines, one of which the Australian government has backed.

At one potential scheme, the Yangibana project in Western Australia, being developed by Hastings Technology Metals, workers are building paved roads around Gascoyne Junction, which sits about 25km to the west of Mount Augustus, an isolated rock hill twice the size of the more famous Uluru, formerly known as Ayers Rock.

The first workers on the site are digging the roads and uncovering large stones, which is making their job harder.

“They’re complaining they are hitting the foothills of Mount Augustus,” says Matthew Allen, chief financial officer of Hastings, which has secured an A$140mn financing loan backed by the Australian government to develop the Yangibana mine as part of its new critical minerals strategy.

Once fully operational in two years’ time, Hastings expects that Yangibana will supply 8 per cent of global demand for neodymium and praseodymium, two of the 17 rare earth minerals and the most in demand.

Other mines coming online in Australia could push that figure toward a third of global supply in the coming years, according to industry analysts.

Rare earth materials

80%

Per cent of the world’s rare earths are produced in China.

These are the minerals used in high-tech products from wind turbines to electric vehicles.

The US and other countries are trying to develop alternative supplies

In the UK, Sharkey at Hovis says he is falling back on his long standing contacts to secure supplies.

“Making sure you are the top of the list, that’s where many years of good supplier relationships come to the fore,” he says.

“You’re really engaging with suppliers at different levels now than we probably were a couple of years ago to ensure that we’ve got continuity of supplies throughout our businesses.”

Businesses directly reliant on Russia and Ukraine for commodities need to be thinking of what lays ahead, he says.

“What does agriculture look like in Ukraine?

Those displaced, when will they be coming back? Will they come back?” asks Sharkey.

“Heads are now turning to what things will look like in the longer term.

There’s a lot of uncertainty for next year and longer.”

Additional reporting by Heba Saleh in Cairo

0 comments:

Publicar un comentario